m.microtech.engineering@gmail.com View Mobile Number

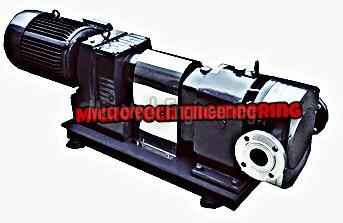

Lobe Pumps

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of Gel Transfer Pumps, Positive Rotary Lobe Pumps, Sugar Syrup Transfer Pumps, Tomato Paste Transfer Pumps and Yeast Transfer Pumps from delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

| Type | Transfer Pumps |

| Certification | CE Certified |

| Weight | 100-300kg |

| Color | Multi Colour |

| Feature | Cost Effective, Durable, Heavy Power |

| Rated Voltage | 230V |

| Rated Power | 1-5kw, 10-15kw |

| Driven Type | Electricity |

| Warranty | 1 Year |

| Automation Grade | Automatic |

| Packaging Details | WOODEN BOX |

Preferred Buyer From

| Location | Worldwide |

Microtech Engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, f ood, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities,high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe. Rotary lobe pumps arenon-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Specifications

- High Viscosity

- Shaft seals

- Externally Timed Gears

- Externally Timed Gears

- High Temperature

- Slow speed for longer wear & longer shear

- Materials of Construction - SS 304 / SS 316

- External Bearing Chamber

- Wide range of drives & Mountings

| Business Type | Manufacturer, Exporter, Supplier, Retailer, Trader, Distributor, Importer |

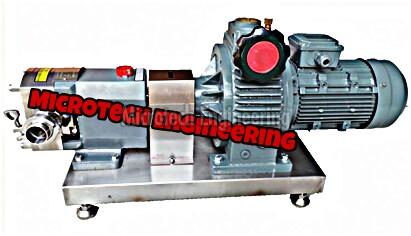

| Type | Rotary Lobe Pumps, LOBE PUMP |

| Certification | CE Certified |

| Weight | 20-300kg |

| Color | MIRROR POLISH |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Rated Power | 0.5 HP TO 50 HP |

| Driven Type | Electric |

| Pressure | 10-20Bar |

| Warranty | 1year |

| Country of Origin | India |

| Brand Name | MICROTECH ENGINEERING |

| Application | FOOD PROCESSING PLANT |

| Fuel | N/A |

| Rated Voltage | 50 HZ |

| Theory | POSITIVE DISPLACEMENT PUMP |

| Power Source | ELECTRICAL |

| Structure | GMP |

| Product Code | RLP |

| Delivery Time | 1 WEEK |

| Packaging Details | WOODEN BOX |

Preferred Buyer From

| Location | Worldwide |

Microtech Engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe. Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

Specifications

- As the rotors start to rotate, an expanding cavity is formed by rotation of the lobes which creates a vacuum at the inlet port, drawing liquid in pumping chamber.

- The product liquid is carried between the lobes and positively displaced, thereby sealing itself against the internal faces of the pump casing.

- The other lobe chamber is filed with the product liquid and about to commence it's discharge cycle.

- Finally the product liquid is forced or pressed out of discharge port of the pump in continuous smooth flow and pressure generated by the meshing of the lobe rotors

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate : Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timinggears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Application : Alcohol - Apple pure Apricots - Baby food Batter Beans Beer Beetroot - Biscuit Cream Blackcurrants Brine Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey Cherries - Chicken paste - Chili con Carne Chocolate Chutney Cockles - Coconut oil - Cod oil Coffee liquor Cordials -Corn oil- Corn syrup Cottage cheese - Cotton seed oil Cranberry --- juice - Cream Cream cheese Custard - Dog food Dough Eggs whole - Egg yolk Essences Evaporated milk -Fish - Iodine - ointment etc

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Transfer Pump |

| Certification | CE Certified |

| Weight | 100-300kg, 300-500kg |

| Color | Multi Colour |

| Rated Voltage | 230V |

| Rated Power | 1-5kw, 10-15kw, 15-20kw |

| Driven Type | Electricity |

| Features | Cost Effective, Durable |

| Warranty | 1 Year |

| Automation Grade | Automatic |

Preferred Buyer From

| Location | Worldwide |

Microtech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate :

- Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create expanding volume on the inlet side of the pump

- Liquid travels around the interior of the casing in the pockets between the lobes and the casing it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

- Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other Positive Displacement Pump types. Since the lobes do not make contact, and clearances are not as close as in other Positive Displacement Pump, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Application : Alcohol - Apple pure – Apricots - Baby food – Batter – Beans – Beer Beetroot - Biscuit Cream – Blackcurrants – Brine –Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey – Cherries - Chicken paste - Chili con – Carne –Chocolate – Chutney – Cockles - Coconut oil - Cod oil – Coffee –liquor – Cordials -Corn oil - Corn syrup – Cottage – cheese - Cotton seed – oil –Cranberry --- juice - Cream – Cream cheese – Custard - Dog food – Dough – Eggs – whole - Egg yolk – Essences – Evaporated –milk -Fish –- Iodine - ointment etc

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Transfer Pump |

| Certification | CE Certified |

| Weight | 100-300kg |

| Color | Multi Colour |

| Rated Power | 1-5kw, 10-15kw |

| Driven Type | Electricity |

| Features | Cost Effective, Durable, Heavy Power |

| Warranty | 1 Year |

| Sound | Sound Proof |

| Automation Grade | Automatic |

Preferred Buyer From

| Location | Worldwide |

Microtech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate :

- Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

- As the lobes come out of mesh, they create expanding volume on the inlet side of the pump

- Liquid travels around the interior of the casing in the pockets between the lobes and the casing it does not pass between the lobes.

- Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

- Lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in lobe pumps than in other Positive Displacement Pump types. Since the lobes do not make contact, and clearances are not as close as in other Positive Displacement Pump, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance. Reductions of 25% of rated speed and lower are common with high-viscosity liquids.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Application : Alcohol - Apple pure – Apricots - Baby food – Batter – Beans – Beer Beetroot - Biscuit Cream – Blackcurrants – Brine –Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey – Cherries - Chicken paste - Chili con – Carne –Chocolate – Chutney – Cockles - Coconut oil - Cod oil – Coffee –liquor – Cordials -Corn oil - Corn syrup – Cottage – cheese - Cotton seed – oil –Cranberry --- juice - Cream – Cream cheese – Custard - Dog food – Dough – Eggs – whole - Egg yolk – Essences – Evaporated –milk -Fish –- Iodine - ointment etc.

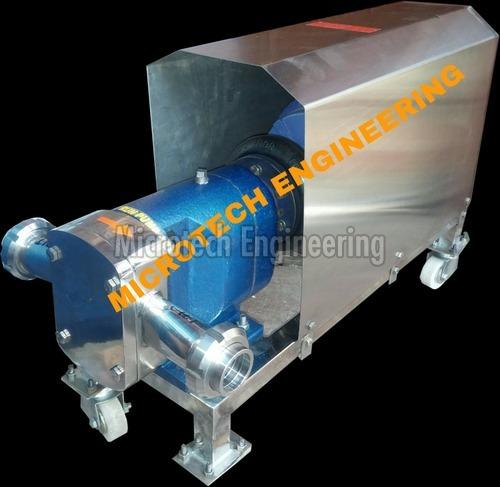

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Transfer Pumps |

| Certification | CE Certified |

| Weight | 100-300kg |

| Color | Multi Colour |

| Rated Voltage | 230V |

| Rated Power | 1-5kw, 10-15kw |

| Driven Type | Electricity |

| Features | Cost Effective, Durable |

| Warranty | 1 Year |

| Sound | Sound Proof, With Sound |

| Automation Grade | Automatic |

Preferred Buyer From

| Location | Worldwide |

We are one-step ahead of our competitors in manufacturing and wholesaling a wide range of Jaketed Stainless Steel YEAST TRANSFER PUMP. These find their wide application in various industries including food processing, beverages, dairy, pharmaceutical and many other allied industries. ergonomic design of these pumps reflect the hard labor and long research work of our experienced engineers. Besides, these pumps also ensure easy installation, corrosion resistance and long functional efficiency.

Specifications

- As the rotors start to rotate, an expanding cavity is formed by rotation of the lobes which creates a vacuum at the inlet port, drawing liquid in pumping chamber.

- The product liquid is carried between the lobes and positively displaced, thereby sealing itself against the internal faces of the pump casing.

- The other lobe chamber is filed with the product liquid and about to commence it's discharge cycle.

- Finally the product liquid is forced or pressed out of discharge port of the pump in continuous smooth flow and pressure generated by the meshing of the lobe rotors

Microtech Enginering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate : Lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timinggears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

Advantages

- Pass medium solids

- No metal-to-metal contact

- Superior CIP/SIP capabilities

- Long term dry run (with lubrication to seals)

- Non-pulsating discharge

Disadvantages

- Requires timing gears

- Requires two seals

- Reduced lift with thin

Application : Alcohol - Apple pure – Apricots - Baby food – Batter – Beans – Beer Beetroot - Biscuit Cream – Blackcurrants – Brine –Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey – Cherries - Chicken paste - Chili con – Carne –Chocolate – Chutney – Cockles - Coconut oil - Cod oil – Coffee –liquor – Cordials -Corn oil - Corn syrup – Cottage – cheese - Cotton seed – oil –Cranberry --- juice - Cream – Creamcheese – Custard - Dog food – Dough – Eggs – whole - Egg yolk – Essences – Evaporated –milk -Fish–- Iodine - ointment etc