m.microtech.engineering@gmail.com +91-9873945272, +91-7503973786

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Pumps |

| Certification | ISO 9001:2008, MSME |

| Application | Agrictulture, Automotive, Industrial, Marine, Power |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

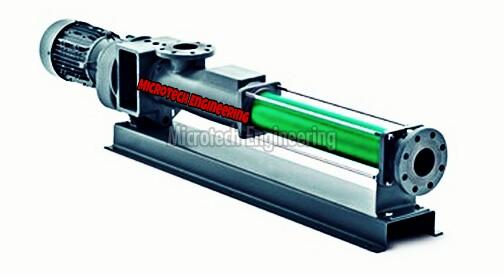

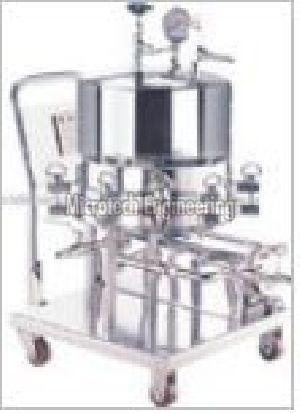

PCP series Progressive Cavity Pumps find their place of applications in almost all the industries in the engineering world. Be it coal slurry or volatile chemicals, harsh abrasives or fibrous pulps, these MICROTECH ENGINEERING pumps are preferred better as right choice. Whenever the pumping is found difficult, these pumps do their duty as per the user’s requirement.

Application

Sewage Sludge, Soap Stock, Sodium Silicate, Spent Grains, Sulphited Syrup, Sugar Syrup, Cane Juice, Varnish, Vegetable Oil and Gum Sludge Viscose, Yeast Acidic And Alkaline Slurry, Alum, Bentonite Slurry, Black Liquor, Casein Slurry, Ceramic Slurry, Clay Molasses, Coating Mix, Detergent Slurry, Ferrite Slurry, Fuel Oil Sludge, Glue, Grout Mix, Lube Oil, Magma, Massecuite, Molasses, Paint, Paper Pulp, Printing Ink, Rosins, Etc.

Features

- Long life, closed or open cardan joints / pin joints.

- Reversible flow direction.

- Suction / Delivery connections in DIN / ANSI / BS

- Housing in CF8, CF8M, Alloy 20 (Fabricated AISI 304, AISI 316, AISI 316l)

- Rotor / Shaft & Rotating parts in AISI 304, AISI 316 & AISI 316L, Alloy 20, Hastealloy, optionally hard chrome plated.

- Torsion free moulded to Stainless Steel / M.S. Tube Rubber Stator in Natural, Nitrile, EPDM, Hycar, Butyle, FPM, Silicon, Hypalon.

- Shaft Sealing by Stuffing Box Gland Packed / Mechanical Seal